FACILITIES

- 51700 sq ft of land.

- Industrial warehouse of 22600 sq ft with a free height of 23 ft.

- Loading and unloading dock with capacity for heavy trucks.

PRODUCTION MACHINERY

- Two Tsugami M08SY CNC lathes with 2 spindles, live tools, Y axis and automatic bar feeder.

- One Tsugami M08SY CNC lathe with 2 spindles, live tools, Y axis and gantry system.

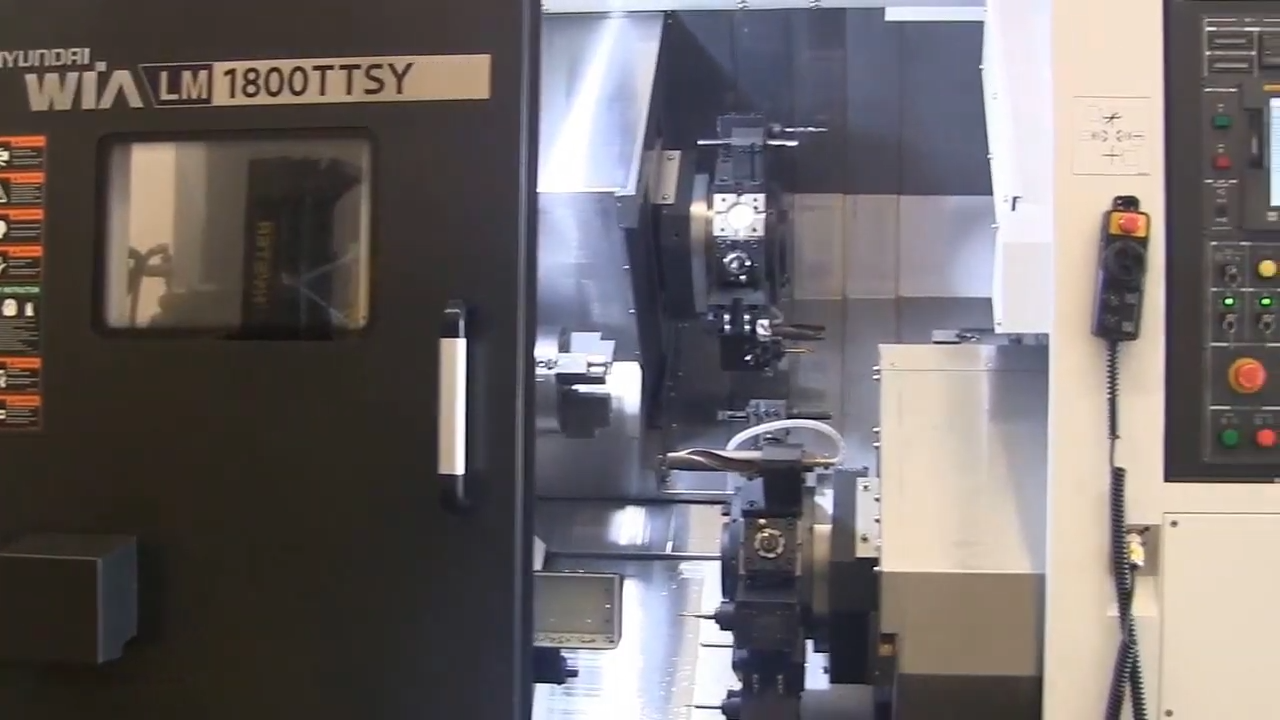

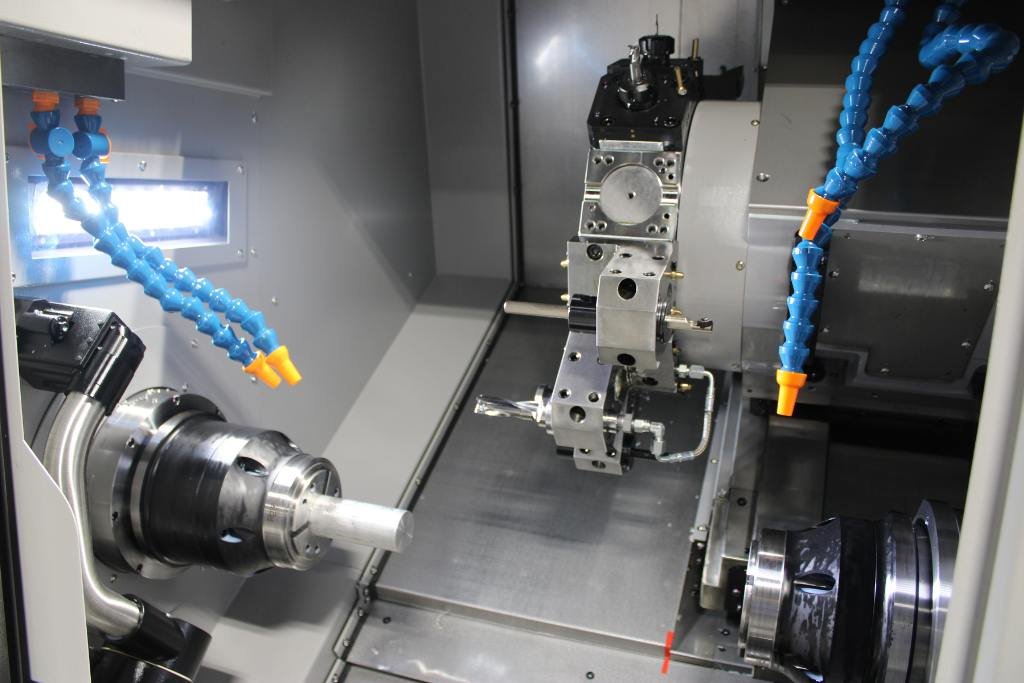

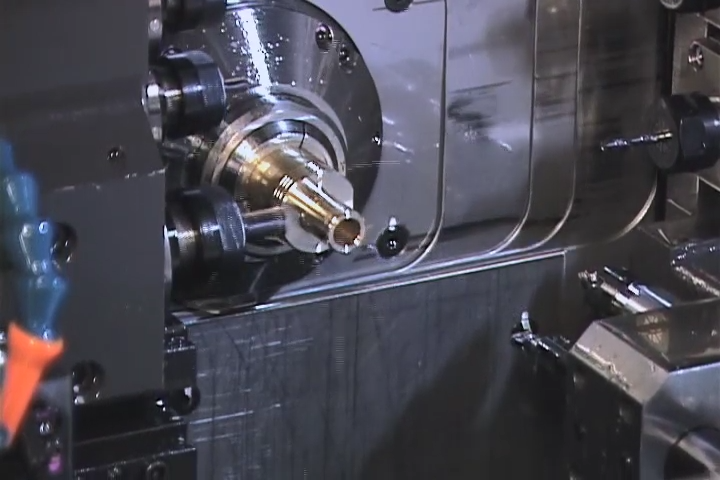

- One Hyundai Wia LM1800TTSY CNC lathe with 2 spindles, 2 turrets, rotary tools, Y axis and automatic bar feeder.

- Two Tsugami B0325 CNC swiss type lathes, 5 axis and automatic bar feeder.

- One EMCO, EMCO Turn 425 CNC lathe with automatic bar feeder.

- One Maier Pro Line ML26D swiss type CNC lathe with 9 axis and automatic bar feeder..

- One Star SV-32J swiss type CNC lathe, with 5 axis and automatic bar feeder.

- One Mori Seiki NH-5000 horizontal machining center.

- One Hyundai Kia KH-40G horizontal machining center.

- Two Haas SL/ST-30 CNC lathes.

- Two Haas SL/ST-20 CNC lathes.

- Two Doosan Lynx 300 CNC lathes.

- One Doosan Lynx 220 CNC lathe.

- One Doosan Puma GT2100B CNC lathe.

- One Tsugami VA-3 vertical machining centerde (3 axis).

- One Hardinge VMC600II vertical machining center (3 axis).

- One Haas Super Mini Mill vertical machining center (4 axis).

- One Hitachi Seiki CS-20 vertical turning cell.

Measuring Equipment

- One Mitutoyo Crysta Plus M CMM.

- One Mitutoyo PH-20 profile projector with computer system.

- One Mitutoyo QM series height measuring system.

- Two KEYENCE image measuring systems.

- One Mitutoyo Contracer CV-3200.

- One Mitutoyo roundness tester.

- Two Mitutoyo roughness measuring machines.

- One hardness tester (Rockwell).

- Various calipers, micrometers, gauges and special measuring systems (Marposs).

COMPLEMENTARY MACHINES

- One WMW profile grinder.

- Two cylindrical grinders with digital readout.

- One Kinefac hydraulic thread roller, 1” of capacity.

- One Kinefac hydraulic thread roller, 1” of capacity.

- One Royal Master centerless grinder (1” max diameter).

- One ELB (flat surfaces) grinder with 10” x 16” magnetic table and digital readout.

- One Colonial hydraulic horizontal broach.

- One horizontal band saw with bar feeder.

- One Baltec RN331 orbital riveter.

- One Sunnen MBC-1801 honing machine.

- Two vibratory tumblers.

- One sand blast cabinet.

- One Bridgeport milling machine.

- One TOS manual lathe.